Basic Info.

| Model NO. | TWO PIECE |

| From 16inch Till 33inch | From 10inch to 49inch |

| Two Piece Type | 3 |

| Forged Steel Sc 40 | Life at Least 5 Years |

| Transport Package | Standard Wood Box |

| Specification | CE |

| Trademark | RAY |

| Origin | China |

| HS Code | 8480790090 |

| Production Capacity | 500 Sets Per Year |

Product Description

BEST MATERIAL- Forged steel SC40

LONG LIFE- At least 5 years life .

HIGH PRECISION- No any flash , no any gap .

GOOD HEAT TRANSFER- curing time are short than old type .

Customer : ELASTOMERIC, SOLIDEAL , UNIGOM. CARLISLE . BRIMELS. APOLLO. JK TYRE .

| Construction | OD | parts | cavity | SURFACE | life |

| TWO PIECE | 6 INCH TO 49 INCH | Top&bottom&core&ring | leakage tested | Chromed-plated | 10 years |

| SEGMENTS | 13 INCH TO 33 INCH | 7 PARTS | leakage tested | Chromed-plated | 10 years |

Company Profile:Our Company is a professional tyre mould& rubber machine manufacture in China. We have more than16 years' experience in rubber industry. Our have served hundreds of overseas customers. We also provide professional after-sale service and product maintenance to satisfy all your needs. Our product Catalog includes: Mouldseries: Tyre mould, bladder mould, solid tyremoud ,air spring moud,agr mold &industrial mould, inner tube mould& flap mould,building drums for all tire tyres. Rubber machine series: Mixing mill, press machine, hydraulic press,tyre building . Steel-wire extruding and Cracking mills. Capacity of mould production: 50 sets of moulds per month.

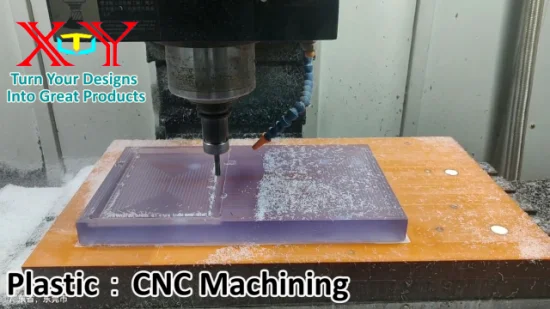

- 2D &3Ddrawing design for customer by CAD / CAM .

- Use good materials &Precise cnc machine to produce. Turnning lathe:Diameter from 100mm to 2800mm.

- Tread pattern were made by EDM specified machine, electrode were made by CNC machine which diameter OF loading is from 400mmto 2000mm.

- Your trademark on tyre sidewall will be engraved by CNC mill machines. We have 3 axes,4 axes and 5 axes to satisfy different requirements.

- 5 steps of quality inspection to achieve customer's requirments, check the run-out &T.I.R of mould, assemble testing .

| MAXIMUM DIAMETER | 2000MM |

| MAXIMUM THICKNESS | 1200MM. |

| MAXIMUM WEIGHT | 6000KG. |

RAY could supply whole design for your new moulds project according to the original size moulds. The drawings for tire moulds are designed with the considerations of mould durability, convenience of assembling, safety function, Curing press fitting availability, to reduce defects or tiny faults in tire production.Your design ideas and specification which include special requirements are checked and studied by our highly skilled experienced engineers. Then we combine know-how and expertise into your requirements for manufacturing the best tire mould. Good moulds are born through a very high level of workmanship and an understanding of your requirements and requires. When such a faithful workmanship is put into production and applied to the mould manufacturing, a very high standard of tire mould is manufactured. We have made many improvements and research over the years. We can offer tire pattern design,3D Modelling,Mould Drawing, Lettering Drawing and Pattern Design Simulation in technical area , based on the technical data. A Mould is a very important piece of equipment which determines the final process of tire production. Company value is depending on the dignity of how good tires you produce. You have to use good tire moulds to produce good tires. With RAY tire moulds you will upgrade your tire level. Focusing on your tires, Your will understand how important tire mold is. FAQ : 1.Question : Are you a factory or trading company ? Answer: We are an SGS recognized OEM / ODM manufacturer and trading company with ISO9000 and export license. 2. Question : Why choose cooperate with us ? Answer : -We have more than16 years'experience in rubber industry. -We have highly experienced engineers and skilled workers.-Wecould supply whole drawing design, production, assembling, testing, maintenance.3. Question : Where is your factory located ? Answer: Our factory located in Qingdao city, Qingdao port is so convenient ,so you will receive your product as soon as possible.4.Question :What is your mission?Answer: :Do our best to set up and maintain a bridge. Through this bridge ,Chinese high quality tyre mould & rubber machine with competitive price will serve more friends of the world.