Plastic Injection Double Color Mold with ABS+Tpumaterial for Bluetooth Speaker

Package Size 350.00cm * 100.00cm * 10.00cm Package Gross Weight 380.000kg Design Points and Types of Double Color Molds

Basic Info.

| Model NO. | M-926 |

| Mould Cavity | Single Cavity |

| Plastic Material | ABS |

| Process Combination Type | Single-Process Mode |

| Application | Household Appliances, Electronic, Home Use |

| Runner | Hot Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | TS16949, CE, ISO, FDA |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | 3 Years |

| Transport Package | Customized or Color Box |

| Specification | 350*100*10 |

| Trademark | OEM |

| Origin | China |

| HS Code | 3901100001 |

| Production Capacity | 500set/Years |

Packaging & Delivery

Package Size 350.00cm * 100.00cm * 10.00cm Package Gross Weight 380.000kgProduct Description

| Double Shot Injection Mold | Size | Depends on Customers Requirement(2D/3D) |

| Color | Multi | |

| Function | Plastic Parts for Home Appliances Parts | |

| Material | ABS+TPU | |

| Brand | OEM | |

| Mould | Type | Prototype and series,production mold |

| Standard | HASCO,DME,LKM,other | |

| Cavity/Core Materla | S136,NAK80,718H,Other | |

| Injection | Cold Runner/Hot Runner | |

| Cycle Life | 500K-1000K Shots | |

| Service | One Stop Service | Design,Mockup,Manufacturing,Assembly |

| Design | CAD/CAM,UG,etc. | |

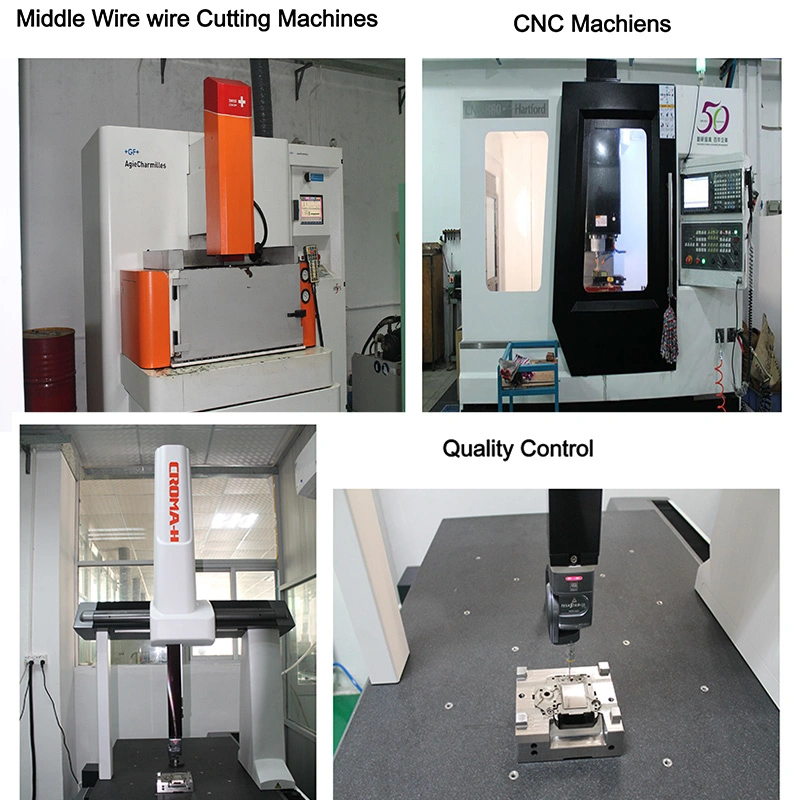

| Mockup | Rapid laser mockup/CNC Mockup process | |

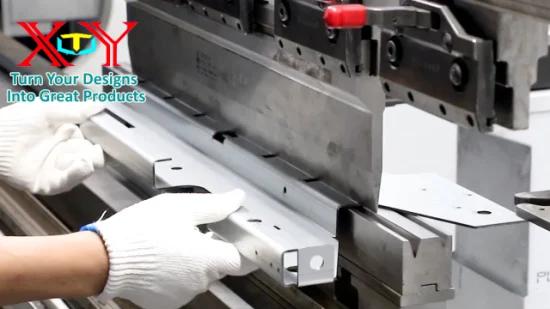

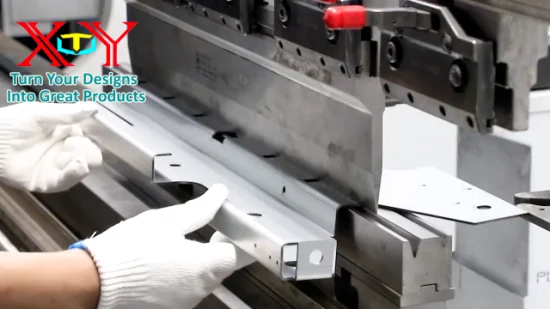

| Manufacturing | Prototype,production mold,parts production | |

| QC | Timely feedback to manufacturing department | |

| Delivery | Sea or Air shipment for Mold/Mass production |

| Product Description | Plastic Injection Mould |

| Part Name | Double Color Mold |

| Key Specification | Bluetooth Speaker Parts |

| Double Shot Mold | |

| Bi-Material Mold | |

| Two-Shot Mold | |

| Two Color Mould | |

| 2*2 Cavities | |

| Two Cavities and Two Core | |

| Horizontal Rotary Injection Press | |

| 2 Shots on the Same Injection Press | |

| H136 Steel | |

| HASCO Standard |

Design Points and Types of Double Color Molds

Double Color Mold Types

Double Color molds can be divided into:Core rotary type,core back type,push plate rotary type according to the structure classification.Among them,the core rotary type can be divided into two types:Split type and conjoined type.The so-called split type is to use two pairs of molds installed on an injection molding machine to complete the injection molding of two-color products,and the conjoined type is a pair of molds.The injection molding of two-color products is completed in China,among which the core rotary split type is widely used.

Design Points of Dual Mold1.Forming PartThe molding part of the dual color injection mold is basically the same as that of the general injection mold.The difference is that the punch of the injection mold at the two positions should be considered the same,and the punch should be well matched with the two punches.Generally,the molded plastic parts are small.2.Demoulding MechanismSince the double color plastic parts can be demolded only after the secondary injection,the demolding mechanism on the primary injection device will not work.For a horizontally rotating injection molding machine,the ejection mechanism of the injection molding machine can be used for demoulding and ejection.For a vertically rotating injection molding machine,the ejection and ejection mechanism of the injection molding machine can not be used,and a hydraulic ejector can be set on the rotary table mold mechanism.3.Pouring SystemSince it is 2K shot injection molding,the gating system is divided into a gating system for one injection and a gating system for two injections,which come from two injection devices respectively.4.MotifDue to the special molding method of dual color injection molding,it needs to cooperate and coordinate with each other,so the size and precision of the two pairs of mold guide devices should be consistent.For a horizontally rotating injection molding machine,the closed heights of the molds should be the same,and the centers of the two pairs of molds should be on the same turning radius,with a difference of 180.For a vertically rotating injection molding machine,the two molds should be on the same axis.

Development and Application of Double Mold

From the characteristics and applications of multi-color injection molding and dual-material co-injection molding,it can be seen that there is a trend to gradually replace the traditional injection molding process in the future.The innovative injection molding technology not only improves the precision of the injection molding process,provides difficult process technology,but also expands the scope of the injection molding process field.Innovative injection equipment and processes are sufficient to meet the demand for more and more diverse,high-quality,high-value-added products.

Dual color injection molding has now been widely used in almost all plastic fields such as electronic products,power tools,medical products,home appliances,toys,etc.The production and molding of double color molds,as well as the research and development of dual color multi color injection molding machines and double color injection molding raw materials have also developed rapidly.

FAQ

Q: When can I get the price?

A: We usually quote within 24 hours after we get your inquiry.If it is very

Urgent,please call us or tell us in your email so that we will regard your Inquiry as priority.

Q:How long is the lead time for mold?

A:It depends on the mold's size and complexity.Normally,the lead time

Is 25~35 days.If the olds are very simple and not in big size,we can work out with 10 days.

Q:Will my drawings be safe after sending to you?

A:Yes,we will keep them well and not release to the third party without your permission.

Q:How to respond quickly to products?

A:If you contact us by email,Wechat,Whatsapp,we promise to reply you within 8 hours.

Send to us